CO2 laser cutting and engraving has revolutionized the design and personalization industry. This versatile and precise technology uses a carbon dioxide laser to make clean cuts and detailed engravings on a wide variety of materials. From wood and acrylic to leather and paper, the CO2 laser offers endless creative possibilities. In this article, we will explore in detail how this technique works, its popular applications, and the benefits it offers designers, craftsmen, and manufacturers.

What is CO2 laser?

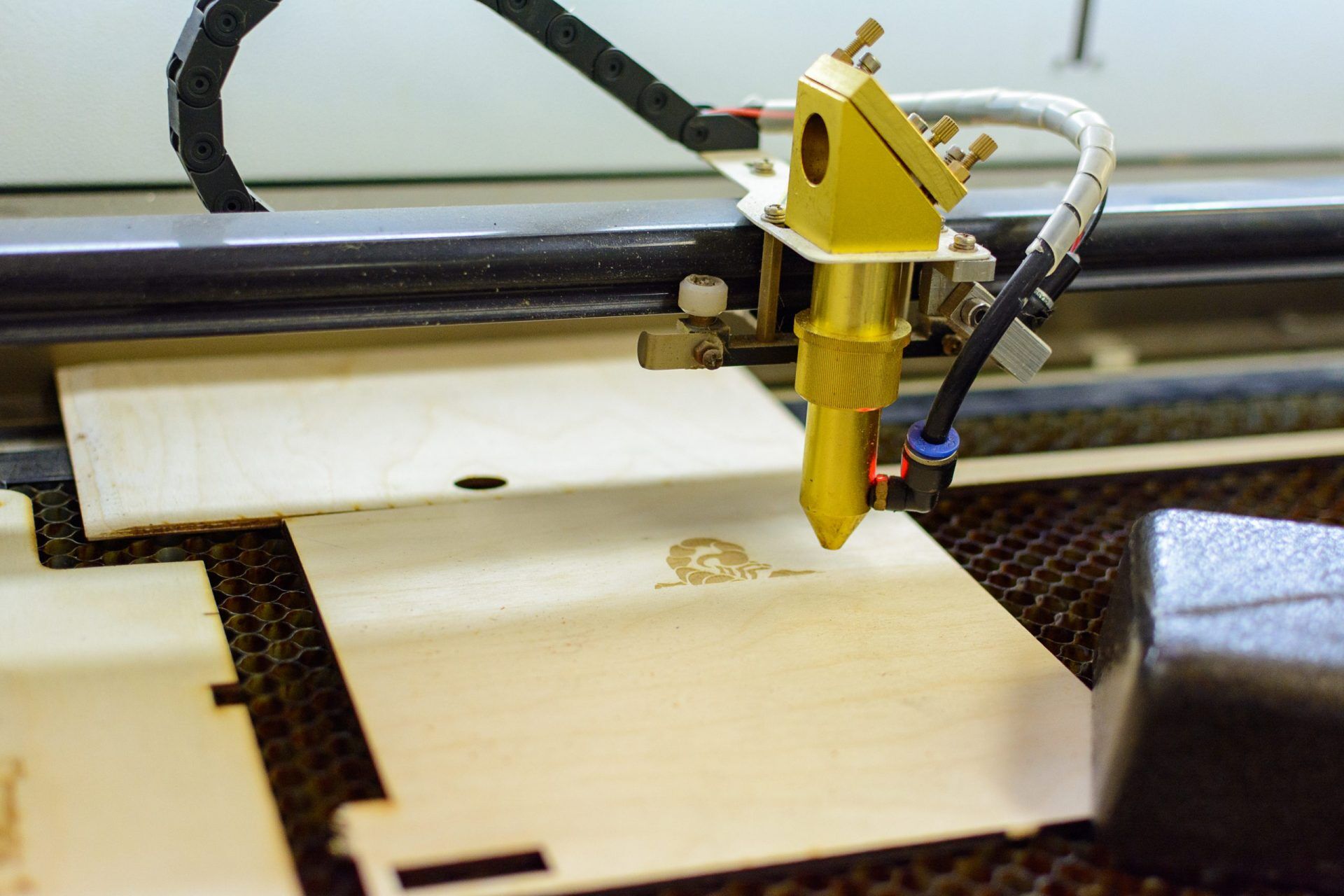

The CO2 laser is a device that uses carbon dioxide gas to generate a highly concentrated beam of light. This light is focused on a specific point, allowing materials to be cut or engraved with precision and detail. The wavelength of the CO2 laser is especially suitable for interacting with non-metallic materials, making it an ideal tool for a wide range of applications.

How CO2 laser cutting and engraving works

The CO2 laser cutting and engraving process involves several stages. First, a design or pattern is created in computer-aided design (CAD) software. This design is then sent to the CO2 laser machine, which adjusts the laser power and speed based on the selected material. The laser focuses on the designated area of the material and heats it until it melts or vaporizes, creating the desired cut or engraving.

Applications of CO2 laser cutting and engraving: CO2 laser cutting and engraving has numerous applications in different industries. Some examples include

- Design and manufacturing industry: allows the production of prototypes, architectural models, mock-ups and customized products.

- Crafts and decoration: can be used to create jewelry, signs, personalized gifts, wood and glass engravings, and more.

- Textile industry: enables the cutting and engraving of fabrics, leather and other materials for the manufacture of garments, accessories and textile decoration.

- Stationery and card making: allows the creation of wedding invitations, greeting cards, personalized packaging and more.

Benefits of CO2 laser cutting and engraving: Using the CO2 laser offers numerous benefits, including:

- Precision and detail: The CO2 laser allows for extremely precise cutting and engraving, even on intricate and complex designs.

- Versatility: Can work with a wide variety of materials, including wood, acrylic, paper, cardboard, leather, textiles and more.

- Efficiency: The CO2 laser cutting and engraving process is fast and efficient, allowing parts to be produced in less time compared to traditional methods.

- Customization – Offers the ability to create unique and personalized designs, meeting individual customer needs and preferences.

- Flexibility: The CO2 laser allows the power and speed of the laser to be easily adjusted, providing the ability to perform different types of cuts and engravings on various materials.

- No physical contact: Unlike other cutting or engraving methods, the CO2 laser does not require physical contact with the material, reducing the risk of damaging or deforming it.

- Energy Efficiency: The CO2 laser is more energy efficient compared to other cutting and engraving technologies, which can result in lower energy consumption and reduced operating costs.

Tips and Considerations: If you are interested in using CO2 laser cutting and engraving, here are some tips and considerations to keep in mind:

- Make sure you purchase a quality and reliable CO2 laser machine, preferably from a well-known manufacturer in the market.

- Familiarize yourself with the computer-aided design (CAD) software used to create the designs. This will allow you to take full advantage of the laser machine’s capabilities.

- Learn about optimal laser power and speed settings for different materials. This will help you achieve accurate and quality results.

- Always keep safety as a priority. Wear protective glasses and be sure to follow the manufacturer’s recommendations to operate the machine safely.

Conclusion: CO2 laser cutting and engraving is an exciting technology that has transformed the way designers, craftsmen and manufacturers create personalized products. Its versatility, precision and energy efficiency make it an invaluable tool in a wide range of industries. Whether you want to do design, craft or manufacturing work, the CO2 laser gives you the ability to bring your ideas to reality with impressive results. Explore this fascinating world and let your creativity fly!